For Has Vida, our customers and their needs are top priority. For that, we constantly invest in innovation to provide a world-class service for all our partners.

Our story started in 1969 in a 150 m2 area with 10 machines. Today it continues with rapid globalization, in a 12.500 m2 facility area, with 200+ high-tech machines and 1 million production capacity per hour.

We know that every invisible detail of tiny fasteners is of great importance. That is why we produce the highest quality custom-designed fasteners using our 50+ years of industry experience. We serve the category leaders in Türkiye and across the globe, in the automotive, electronics, and white good appliances industries.

We add value to our customers by providing reliable and sustainable partnerships through our smart thinking and pride in our work. We care for our customer relationships and place utmost attention on timely delivery.

For us, “A successful company does not focus on producing large quantities, but rather on delivering the highest quality." and we instill this understanding at every stage of our production.

We live in harmony with Industry 4.0 and never distance ourselves from technology. Our innovative working model allows us to grow continuously as a company.

At Has Vida, we value open and transparent communication. We never sweep anything under the rug! Instead, we address everything that needs discussion through a constructive model. This approach enables us to build strong communication bonds with our customers and employees.

Even in the most unexpected situations, we show the utmost agility to address our partners’ problems in the fastest way possible.

We firmly believe that nothing can surpass our industry knowledge and experience. We make sure to reflect this expertise in every stage of our production.

We go beyond being just a screw manufacturer by establishing strong and sincere relationships with our customers and employees. We focus on trust and loyalty by building long-term connections.

We are aware of the importance of small fasteners. We are here to create value-added “connections” with open-minded, dynamic, and human-centered strategies.

With our passion for generating innovative solutions, we aim to lead the industry globally by developing patented products and solutions that propel the industrial sectors forward.

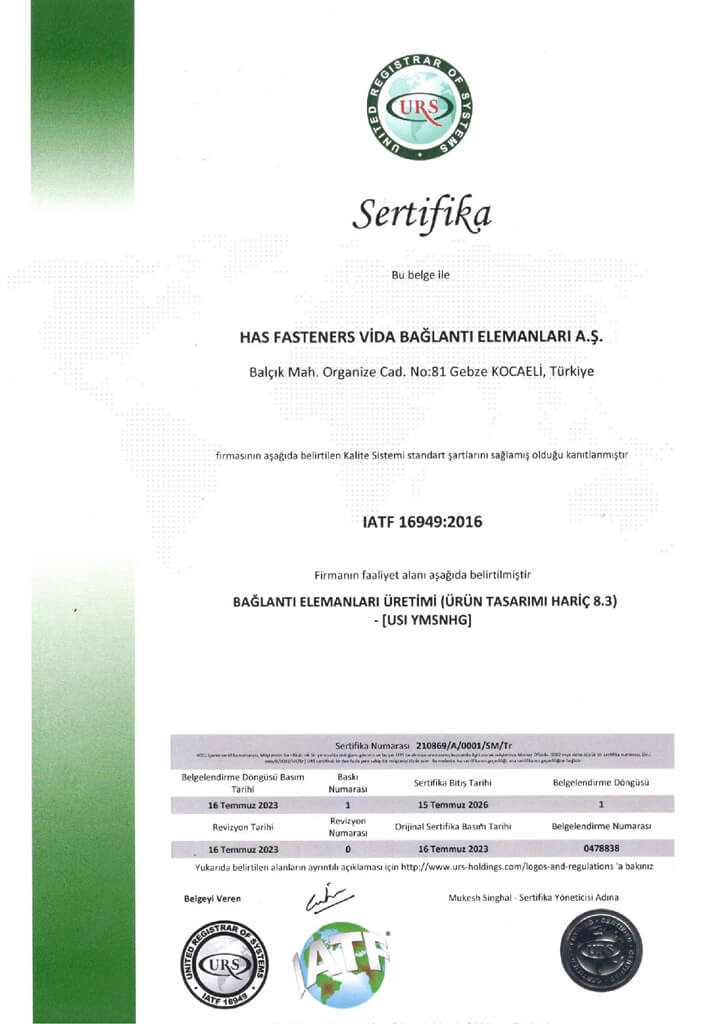

Quality Management Systems

Customer Satisfaction Management System

Environmental Management Systems

Occupational Health and Safety System

Automotive Quality Management System

We always prioritize sustainability principles in the products we manufacture and the services we provide. We believe it is important to serve our employees, society as a whole, our environment, and ultimately our world in every step we take. We continuously improve our business model, striving to be at the forefront of change; by researching areas to enhance efficiency and searching for ways to make energy savings.

We established a filtering mechanism in 2020 in order to filter the used oils in production. Through this method, we made it possible to reuse this oil in the machines. We have reduced our oil purchases by 24.6% within 18 months thanks to this systematic reduction in oil consumption.

With the systematic arrangements developed by our engineers, we are creating less waste and scrap every single day. Our scrap reduction projects we started back in 2019 made it possible for us to reduce scrap and waste by 26% between then and now. Today, we continue our production by using 5 tons of lesser steel on a monthly basis.

For impeccable products that complies with DIN and ISO standards:

Has Vida © 2025. All Rights Reserved.

Size en uygun seçeneği tercih ederek, fiyat teklifi taleplerinizi tarafımıza iletebilirsiniz.

You can send us your quote requests by choosing the option that suits you best.

Aşağıdaki formu doldurarak, fiyat teklif talebinizi tarafımıza iletebilirsiniz. Satış ekibimiz size en kısa sürede dönüş sağlayacaktır.

Aşağıdaki formu doldurup, listenizi yükleyerek fiyat teklif talebinizi tarafımıza iletebilirsiniz. Satış ekibimiz size en kısa sürede dönüş sağlayacaktır.

You can send us your quote request by filling out the form below. Our sales team will get back to you as soon as possible.

You can send us your quote request by filling out the form below and uploading your list. Our sales team will get back to you as soon as possible.