In our R&D center, we custom design special parts and products tailored to our partners’ needs.

We took our adventure in fastener manufacturing, which we started in 1969, to higher levels with the approval of our R&D Center by the Ministry of Industry in May 2023.

Utilizing the latest manufacturing and laboratory technologies, along with our beneficial models in innovation processes, our patents and new products, we will continue to work at an even higher level.

Our R&D Center aims to increase our share in both localization and the global market through its work with different raw materials and product types day by day.

In our mini factory we built for technical training; We ensure that our employees constantly keep their knowledge up-to-date on the machines, machine parts, quality devices and molds involved in production and we regularly provide efficient training.

We improve our production processes and products by following the opportunities created by developing technology every year.

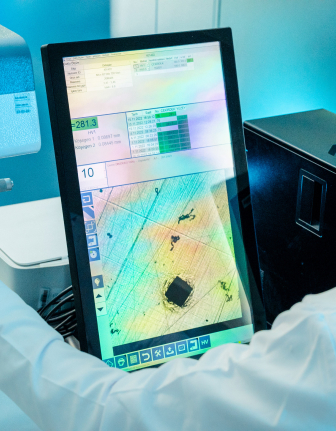

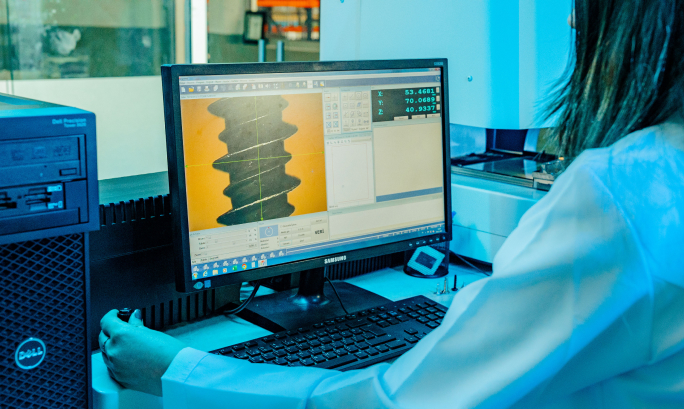

While we improve the geometric structure of the product and increase its functionality through 3D supported programs, we also improve the construction of the molds required for cold forging. We optimize the construction of molds required for cold forging. Furthermore, we continuously enhance our knowledge and experience in producing more complex and challenging products.

Through long-term collaborations with universities and academics, we carry out one-on-one studies with academics who specialize in cold forging processes and engage in contractual collaborations with universities.

Using 3D technology and digitalization, we accurately determine the required material properties for production and hence plan the processes more accurately as well. We thoroughly analyze all production processes from material selection to packaging and we design them according to the specific needs.

With simulation studies, our aim is to minimize the PPM (parts per million) rates in production processes, approaching rate zero except for natural variations.

Through the theoretical and practical training provided by university professors, we equip our employees with the technical knowledge needed to design the highest quality products. The technical trainings enhance the knowledge and expertise of our R&D center, while also contributing to the awareness and development of our field personnel.

For Products Special to Your Needs with R&D Supported Designs:

Has Vida © 2024. All Rights Reserved.

Size en uygun seçeneği tercih ederek, fiyat teklifi taleplerinizi tarafımıza iletebilirsiniz.

You can send us your quote requests by choosing the option that suits you best.

Aşağıdaki formu doldurarak, fiyat teklif talebinizi tarafımıza iletebilirsiniz. Satış ekibimiz size en kısa sürede dönüş sağlayacaktır.

Aşağıdaki formu doldurup, listenizi yükleyerek fiyat teklif talebinizi tarafımıza iletebilirsiniz. Satış ekibimiz size en kısa sürede dönüş sağlayacaktır.

You can send us your quote request by filling out the form below. Our sales team will get back to you as soon as possible.

You can send us your quote request by filling out the form below and uploading your list. Our sales team will get back to you as soon as possible.